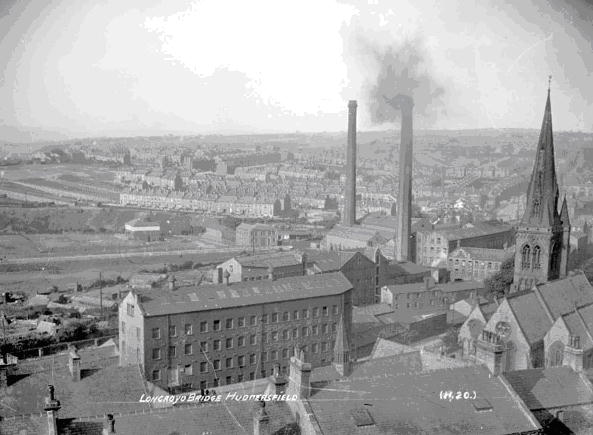

STARKEY’S FACTORY – LONGROYD BRIDGE

In 1819, on a narrow strip of farmland at Longroyd Bridge, bounded by the curve of the canal on the north and the river Colne on the south, Starkey, Buckley & Co. began to raise what became for many years the largest woollen factory in Huddersfield. It is one of the ironies of Huddersfield’s history that , only yards away, stood the cropping shop of John Wood, where seven years earlier the Luddites had planned their campaign to halt the advance of machinery.

The main partners of the firm, Joseph, Thomas and John Starkey were woollen merchants who had previously undertaken some manufacturing in premises at Pedley’s Mill, Paddock. They had accumulated enough wealth to buy a small mansion at Spring Dale, just across the river from where they established the mill. Expansion continued with the acquisition of three more plots of land at Longroyd Bridge in 1831. By the early 1830’s the firm became known simply as ‘Starkey Brothers’ and their premises, making plain woollen goods, was one of only a handful in the Huddersfield area deserving of the name factory, carrying out all the stages of manufacturing from the scribbling of wool to the dyeing and finishing of cloth. In 1833, the mills, powered by three 28 horse-power steam engines, employed 521 people, 135 of them female and 73 of them under 14. 1

The factory was one of the earliest to introduce power into woollen weaving and in 1835 it was reported that four power looms a week were being set up. A total of 70 were to be installed. Men were already being laid off, to be replaced, so it was later claimed, by cheaper female ‘ power loom tenters’ , paid an average of 7s.6d a week. Even this was reduced to 6s resulting in a strike. It was estimated that a piece which a hand loom weaver had formerly produced for £3.00 now cost only 14s by power. 2

The following year 72 pairs of Power looms were insured for around £10.10s each, and the total machinery valued at £18.654. The buildings were insured for about one third that of the machinery and comprised two five storey mills for spinning, weaving and finishing; the four storey ‘Cross Factory’ (at right angles to the main east-west alignment of buildings), for spinning; press shops, boiler house and stove; the Old Factory with three floors for scribbling and fulling; the East factory of five storeys for scribbling, spinning, finishing and the engine and boiler houses. 3

The Starkey Brothers were strongly opposed to the Ten Hour Act to limit child labour, being numbered among the ‘Factory Mongers’ by the radical Voice of the West Riding. Its editor, Joshua Hobson, cryptically alluded to the Starkey’s lowly origins as ‘back of the counter men… having some years ago tired of their call at Croppers Row and Commonside, next to the Poor House.’ Thomas Starkey also supported the election campaign of the Whig candidate in 1833, further antagonising working class radicals. A notice was posted at the mill threatening to dismiss anyone whose absence from work coincided with a meeting of the Radical candidate, Captain Wood. Joseph Starkey was accused of ‘exclusive dealing’ (boycotting) by ordering his gardener not to buy seeds from a supplier who had voted for the pro- Ten Hour Bill Tory, Michael Sadler. The Starkey Bros. were also actively opposed to Trade Unions, signing a resolution along with other manufacturers not to employ anyone ‘who does not bring a good character in writing from his previous master’ – that is a reference stating he was not an unionist. This probably accounts for the lack of evident union activity at the mill, apart from donations to strikers in Derby sent to Robert Owen’s periodical the Pioneer by ‘A few friends at Starkeys’ Factory, Longroyd Bridge’. In 1839 the firm sacked seven workers, two of them with 19 years service, for their Socialist opinions. One of these was the foreman of the dyeing department, George Brook, who had procured the site for the Socialist’s Hall of Science. For him it proved a blessing in disguise, since he eventually established his own business at Larchfield Mills , Firth Street. One, possibly Brook himself, was unsuccessfully asked to return, since his replacement was damaging so much cloth. On the Saturday (13 August) of the ‘Plug Riots’ of 1842 strikers arrived at the mill gates. When Joseph Starkey, now a magistrate, read the Riot Act some of his men offered to help defend the mill, but the crowd forced their way in and ‘plugged’ the boilers, stopping the engines. An attempt to restart the mill on the following Monday was also thwarted. 4

When, in 1844, it was reported that Thomas Starkey ,‘the largest manufacturer in the neighbourhood’, had implemented 11 hours to help improve ‘the morals and the habits’ of the workpeople, reformers suspected this was really a ploy to undermine support for the Ten Hour Bill. George Brook Jnr claimed that the 11 hour day had only been agreed after the Starkeys were satisfied that the equivalent of 12 hours of work could still be acheived. He listed this and other injustices – including the dismissal of his father, the displacement of men by women power loom weavers and of skilled wool-sorters by apprentices – on a poster attacking Joseph Starkey, the unsuccessful Conservative candidate in the 1853 election. To refute the accusations, which resulted in a libel charge against Brook, 282 foremen and workpeople signed a testimonial in support of Starkey, asserting that the 11 hour day was introduced sincerely. Apparently there wasn’t total contentment at the mill. In 1848 the giggers, who hand raised the cloth, suffered a wage reduction from 20s to 18s following the introduction of the Ten Hour Act.. However a shilling was restored and they were given a sovreign back-pay. In 1860 female slubbers and layers-on resorted to a strike for an extra shilling to bring their wages up to that of other firms. 5

The Starkeys combined patriarchal authority with paternalistic concern, assuming responsibility for the moral improvement and welfare of their workers. After Thomas Starkey’s death from typhus in 1847, contracted, it was said, through helping a sick waif, his widow and brother John founded the imposing St Thomas’s church as a memorial, just across the road from the mill. In 1849, during the cholera outbreak, the firm agreed with Dr Allatt of Paddock to pay workers’ medical bills and efforts were made to sterilise the mill by spreading chloride of lime. The workers ‘spontaneously signed a memorial to the firm embodying their thanks in homely but heartfelt praise’ for the care shown by the firm. Education was also promoted by the financing of two schools while, to encourage thrift, the workpeople and foremen set up a committee to form a savings bank in 1850. The mill also became a focus for recreational activities, as loyalty was fostered by a works cricket team (which played, for example, against Victoria Mill, Lockwood in 1852) and treats and trips became a regular feature of mill life. 6

In 1861 a tea was laid on for the burlers, to encourage the speedy completion of an order and in June 1862 600 workers, plus 400 friends, went on a train excursion to Liverpool. At a treat the following day Lewis Starkey announced that, despite depression, there had been no short time working and, to loud cheers, ‘impressed upon the workpeople that so strong was the desire … to keep them in full work that they were prepared to sacrifice rather than close the mill’. The next year the 600 workers were also given an extra days paid holiday.. The workforce showed its gratitude for the employer’s benevolence by presenting a tea service to one of the partners, Thomas Walker Brook , in 1874. At the ceremony tribute was paid to good relations in the firm and the fact that no short time had been worked in 40 years. A foreman, Richard Moody, said he had been employed there for 33 years. This wasn’t a record. The obituary of ‘Old Ebenezer’ Stanhope in 1891 referred to the 35 years he had worked for Starkeys. Isaac Suthers of Paddock, who died in 1895 aged 79, spent 64 years of his life at the mill ! Some of the old employees received pensions from the firm but it was claimed others ended up in the workhouse. 7

Even the great Huddersfield weavers’ strike of 1883 had little adverse impact on industrial relations. Only about 30 of the weavers were in Weavers Association and there was no grievance with the firm because the disputed pay scales were not introduced. Nor were Starkey Bros. members of the masters’ union, the Manufacturers’ Association. However, at meeting with the union weavers it was pointed out, ‘in a friendly way’, that if they refused work on contracts from manufacturers involved in the dispute, members of the union would not get any new work at Starkeys’ so long as the strike lasted. 8

Expansion and modernisation of the mill continued. In 1841 a mill and dyehouse at the other side of the canal were acquired from Thomas Blackburne . When an inventory of machinery was made in 1857 it was still referred to as ‘Blackburne’s Mill and used for fulling. The ‘Old Mill’, ‘Low End Mill’ and ‘Top End Mill’ are also mentioned. In 1841 the right was granted by Huddersfield Canal Co. to erect buildings along 180 yards of the towing path wall. Alterations were certainly taking place in 1849 when a mason found a hoard of 294 sovereigns during demolition. Following the death of Thomas Starkey a new partnership was established with George Brook, ‘for many years’ cashier and confidential clerk to firm, (not to be confused with the sacked Socialist ! ). His son, Thomas Walker Brook, later undertook much of the running of the mill along with John Starkey’s son, Lewis Randle Starkey. George died in 1884. In 1894 the firm become a limited company and the premises were renamed Springdale Mills. 9

Thomas Brook, in evidence to the 1875 Parliamentary Committee on the LNWR and the canal, stated that in the last ten years £60,000 had been spent on the mill, which now employed 700. During the alterations in 1869 the Huddersfield Examiner claimed that the largest block of stone ever brought to Huddersfield, 11’6″ by 9′ by 2′ and weighing 15 tons, had been transported by Charles Holt’s traction engine to make a bed for a new horizontal engine at the mill. Four years later Holt summonsed Brook, claiming he had not received money for work done between 1868 and 1872 on the boiler house. A steam economiser, engine and boiler made by Galloway & Sons costing £2,650 had been installed, plus £2,500 worth of gearing. Although he was the consulting engineer and not an architect, Holt was contracted for £1,000 to make a plan for the boiler house. He also agreed to arrange the sale of the old engine and boilers. Brook said he had not been paid because he had come up with an elaborate design like the boiler house at Saltaire ! Further work was carried out in 1887 when E.W.Lockwood, architect of Byram Arcade, advertised for tenders. 10

The firm continued to pioneer innovations. In 1888 they tried out fire resistant screens between the scribblers to limit circulation of fluff and, in 1896, patent improvements in the method of and apparatus for consuming smoke in steam boiler furnaces. A representative of Starkey’s went in 1905 on a local manufacturers’ delegation to mills at Gladbach in Germany to see revolutionary carding machines at work. 11

For such a large mill with so many employees remarkably few accidents are recorded. In 1874 a 21 year old female from Berry Brow was injured and in 1895 Joe Bailey, a whitewasher, aged 27 received fatal injuries when his clothing caught in a revolving shaft. It took two to three minutes to stop the engine before he could be cut free. 12

The mill experienced at least four fires in its life, in 1840, in 1860 and another in the drying stove, in 1904. Disaster was narrowly averted later that year when a more serious one broke out in a block of the mill housing spinning and carding machines. Helped by the corporation fire engine, Phyllis, which had to aim the hose from across the canal, damage was limited to two floors and a large quantity of cloth was rescued by the workpeople. The mill was working day and night at the time on a contract for cloth for the Japanese army, then engaged In the war against Russia. 13

But Starkey Bros. days were numbered. On 15 March 1907 Springdale Mill closed down. The premises and machinery were auctioned by George Tinker & Sons, the looms in particular realising very high prices, with even 15 year old ones fetching £30 each. Among the buildings were included a 550 square yard weaving shed and seven multi-storied mills, which had been powered by five Galloway’s boilers running two horizontal condensing engines. The local Socialist paper The Worker expressed concern for the hundreds of employees who had lost their jobs, many too old to find work elsewhere, commenting:

‘Country estates have been bought, commissions in the army purchased, parliamentary elections have been both lost and won, day schools have been built and a church opposite the mill erected and all these and the other accompaniments to wealth and position have accrued from the profits of the mills.’

Any doubts about this opinion must have been dispelled by the death in 1910 of Lewis Starkey ,now of , Norwood Park, Southwell, Nottinghamshire, leaving a gross estate valued at the then massive sum of £ 200,310. 14

[Figure 2. 1907 Sale advert and Plan]

Springdale Mill was leased by a number of different firms, (at least six occupying the premises in 1910) and subsequently underwent many changes of use. All the buildings, which had for so long dominated Longroyd Bridge like a moated fortress between canal and Colne, were finally levelled to the ground in the early 1980s. Saint Thomas’ church still stands as a reminder of the Starkey family, but the mill, the monument to the thousands of local people who laboured in it’s shadow, has disappeared without a trace.15

REFERENCES

Acknowledgements

Thanks to the staff of Huddersfield Local History Library and Kirklees Archive Service for help during this research.

1. Directory 1822, 1830; For date of original mill Factory Commissioners Report, 1834; Thos Walker Brook , Parliamentary Committee on LNWR, in Huddersfield Examiner (Weekly) (HEW) 15 May 1874; The Worker 16 Mar 1907.

2. Leeds Times (LT) 21 Feb, 9 May 1835; HE 2 Apr 1853.

3. Leeds Times (LT) 21 Feb, 9 May 1835; HE 2 Apr 1853. Jenkins D.T. The West Riding Wool Textile Industry 1770-1835 (Pasold 1975) pp.166-168; For a reconstruction see RCHM, Yorkshire Textile Mills 1770-1930 (HMSO 1992) p102.

4. Voice of the West Riding 23 Nov, 28 Dec, 27 Jul 1833; Pioneer 1 Mar 1834; HEW 15 Jan 1881; George Brook [obituary]. )LT 14,21 Dec 1839;New Moral World 28 Jun 1845 ; Leeds Mercury (LM) 20 Aug 1842.

5. LM 13 Apr, 4 May 1844; HE 2 Apr 1853; LM 30 Sep 1848; HE 31 Mar 1860.

6. HE 30 Aug 1975 Chadwick,.S. ‘The Starkeys and their Church’. LM 29 May 1847, Sykes D.F.E. History of Huddersfield p. 149; LM 13 October 1849; LM 6 Apr 1850; HE 31 Jul 1852.

7. Huddersfield Chronicle (HC) 5 Jan 1861; 14 Jun 1862; 14 Mar 1863; HEW 24 Jan 1874; Huddersfield Weekly News 18 Apr 1891. Yorkshire Factory Times (YFT) 18 Jan 1895.

8. HEW 17 Mar 1883

9. West Yorkshire Archive Service, Kirklees KC.135; LM 30 Jan 1849; HEW 31 Jan 1903, T.W.Brook, obituary. The name Springdale first appears in the 1897 White’s Directory.

10. HEW 15 May 1875, Brook explained that the mill relied on water from the canal for its operations.; 10 Jul 1869; 12 Apr 1873; 29 Jun 1887.

11. HEW 3 Nov 1888; 16 May 1896

12. HEW 11 Apr 1874; YFT 18 Jan 1895.

13. LM 17 Apr 1841; HC 12 May 1860; HEW 19 Jul; 15 Oct 1904.

14. The Worker 16 Mar, 27 Apr 1837; KC 135 Sales advert and plan; The Worker 28 Jan 1911.

15. Yorkshire Textile Directory 1910 et.seq.

(All photos by author)

STARKEYS’ MILL 1819-1907.

ALAN J. BROOKE June 2001

LARCHFIELD MILL

See: https://undergroundhistories.wordpress.com/the-brooks-of-larchfield-mill/

FOR PHOTOS OF SOME LOCAL MILLS SEE:

http://www.examiner.co.uk/news/west-yorkshire-news/look-mill-memories-archive-pictures-9131135

FARNLEY MILL – RESTORATION CAMPAIGN

Hi,

I’m coming to stay at titAnnic mills in linthwaite soon and I’d be interested if you have any background on that mill. My family are based in Huddersfield and my grandparents worked in the woollen industry around holmfirth (Washpit Mill) designing worsted cloth of which I still have suit lengths. I’m interested in industrial history and when I return to the area I’m keen to learn more about the past. Any info you have on titanic I’ll would be appreciated

Dear Martin,

thanks for your inquiry. I don’t have much on Titanic sine my main study of local mills only goes up to 1914 and the mill was built only in 1912.

I attach the references I have below. There is some later stuff about the CV Spinning Co but I don’t have this typed up yet.

I have more stuff on Washpit if you are interested in that, but Michael Day has use much of it (and more) in his book on Holme Valley mills ‘Wool and Worsit’.

Cheers

Alan

324. TITANIC MILL (Linthwaite)

1911 CVG 27 Jan: Beaufort Mill chimney felled, ‘a large mill is being erected on the site for the Colne Valley Spinning Company. The new chimney will be about 60 yards high and will be erected within about two yards of the site of the old one.’ Contractors, J. Wimpenny & Co. Linthwaite.

1912. W 10 Feb: during building 40 iron pillars on the ground floor fill with water and are cracked by frost.

Lockwood. P22. CV Spinning Co. Founded by J E Crowther. Floor space 22,691 sq yds.

1914. YFT 8 Jan: Colne Valley Spinning Co (Linthwaite) strike of 20 spinners: not in union: but join: bad mterials : only average 8-9s a week after paying piecers. All dismissed and new hands advertised for.

W. 17 Jan: fund raising. Locked out new year’s eve.

1915. YTD : Colne Valley Spinning Co. 21,000 spindles.

Hi. I am currently in the process of renovating Stanley Mill on Britannia Road, Milnsbridge and wondered if you had unearthed any information on this building. We intend to use the heritage of the mill and the area as part of our branding so any useful information would be much appreciated. Many Thanks, Andrew Lindsay.

Many thanks. I stumbled on your website in an hour of leisure just wandering/browsing the Internet. Born Huddersfield I have lived in Switzerland most of my life. I am still in involved with textiles and, …. what should I say ? have an interest in the past, present and future of mills in the North of England. As a teenager textile student working for extra money to fund my studies, I worked short periods of time at John Edward Crowthers, Bank Dam Mills Marsden, and Middlemost – Bros., Clough Mill Birkby. In my professional career I have visited and consulted, working on the machines at various mills in Lancashire ,,,, Dorma, Arrowvale, Lonrho Newcastle et al. and also many mills around the world Turkey, South Africa, USA, Finland , Germany, France and so on. I also have a couple of good friends (mill owners) from the Huddersfield District.

A long story ! And now, in the autumn of my years my fond memories of Huddersfield and the history of the mills now sadly almost all defunct , I am most interested in obtaining copies of any books , and publications there might be available for sale.

I shall be looking forward to hearing from you

Sincerely

Dwyer

Do you have any information please about Folly Hall’s Mill and the Sykes family. John & George Sykes were partners operating in Wood Street Cheapside London and at the same time from Huddersfield 1812-1827 as warehouse men, clothiers and woolen factors. William Sykes resided at Folly Hall 1778 when he had married Sarah Scholefield from Dalton until 1828 as a cloth dresser and merchant. Was Commercial Inn a part of the Mill as Anby Beatson was listed as an Innkeeper [his son-in-law]

I have changed my e-mail address I am requesting information on John & George Sykes and Folly Hall Mills

Thank you

What I have on Folly Hall Mills is in the catalogue under ‘Kaye’s Factory’. The only other possible source are the trade directories, not all of which I have searched for every mill.

Hi there,

I work at a company called the Design Bank and we are based in a building called ‘Headrow House’ located on Old Leeds Road on the bottom end of town, that we believe is a converted old textiles mill. We’re sat roughly inbetween Waterloo Mills and Turnbridge Mills, next to a converted church.

I was just wondering if you had any information about the history of the mill building, such as the year of it’s contruction and what it was originally called. I’ve had a look online and can’t seem to find a map of the town detailed enough to show it’s old name and such, but I did stumble across your site in the process. Any help would be very much appreciated! Thanks in advance, keep up the great work.

Hannah

Hello,

I came on to your website through the lead to the piecers clipping and cleaning teazles for finishing, and I wondered whether you could please give me the exact reference, as I wasn’t able to find it. This would be very much appreciated,

Thanks,

Robert McMillan

anyone know of the worsted cotton businesses owned by Joah Lodge in the 1800″s

Gaye, Have you searched through the ‘Catalogue of Mills..’ pages ?

My late father worked at John Crowthers Milnsbridge, he started as an office boy, through hard work and going to tech he gained his ACIS and ACIA and became the company secretary, I worked in all the school holidays in the joinery shop and metalwork shop, so went all around the mill complex, I was there when the first Sulzar looms came from Switzerland,the floor had to be re-laid to be perfectly flat, I helped in getting these big (to me) machines in place, this was the era of Joe Hymen, my dad was often whisked down to London at a moments notice in the company Rolls Royce, my dad prefered the new Audi 100Ls that they had just bought. It was also the unrest in Ireland and my dad decided to move on after over 40yrs.

Thanks, Alan, for this information.

My mum worked at John Crowthers – Milnsbridge, as a teenager in 1935- here is part of her account

” …. I left school at 14yrs. I wanted to go into Shop work but my Dad said it was the was the MILLS for me- so I started work in a WOOLLEN MILL- and had to begin at 7-15am until 5-15pm with half hour for dinner time – I had to learn to wind the BOBBINS for the weavers to fill their SHUTTLES and my wage was 5/- a week, and then I got 8/- a week.

……………..

I didn’t like in the MILL, but I had to stay there- a girl who worked with me, said we ought to move on – but we were told we could learn to weave on Northrop looms- and we had three hours each – it was very hard work and we only got paid 13 shillings at first – Then we were 16 and asked for a little extra and we got 21 shillings!

But we decided to leave, and one dinner time- Vera had a bike and we went on her bike over

Milnsbridge a large mill – John Crowther and Sons , and so we started work there.

That was a better organised place and huge weaving sheds, a Northrop’s shed- and a Dobcross shed. Hundreds of looms and workpeople. We had to catch a bus at 6.30am, and be there for 7am…..”

Thankyou for this interesting information.

I’ve just come across your comment on John Crowthers. Your father must have been at Crowthers at the same time as mine. He was often away from home in the 70s, particularly in London at the behest of Joe Hymen. Dad worked in the design office, I think, having worked his way up during the ’50s and ’60s. He left Crowthers in the late ’70s and went to Firth Brothers, Shepley.

I am currently engaged in writing a book on my family history, which is primarily intended for my daughter, sister and some other family members to give them an insight as to the lives of their ancestors. I am descended from William Learoyd, who was a woollen mill owner in Huddersfield, and one of his later descendants, Alfred Ernest Learoyd was instrumental in designing and building Trafalgar Mill. I was wondering if there are any remaining employees of this particular mill still living, with memories of the tasks they carried out, along with and their working conditions. I do not live in Yorkshire, and can rarely make the trip to Huddersfield owing to family constraints, so any contribution would be greatly appreciated and welcomed.

Dear Kath,

i’m afraid I don’t know of any ex-employees. I have done little on the oral history, my main interest being the pre-1914 industry. Vivian Teasdale, author of ‘Huddersfield Mills – a Textile Heritage’ may know more about Trafalgar Mill. I don’t have her contact number but perhaps you could find out via her publisher -Wharncliffe Books

Hope you find the info you are looking for,Best Wishes

Alan

Hi i wonder if anyone has any information on the Malham Place Works on Almondbury Bank which we believe was connected to the mill textile trades. The only information i have at the moment is that there was a very big fire there over 40 years ago, the frame of the building stayed together with the internal steps as they were made of stone. The building as it stands at the moment has been turned into offices but i am sure that someone out there will know a little about this building. Help Help Help if you even have a small snippit of information. Thanks

How do I contact Alan Brooke to thank him for his research on “Mills” [esp. REF:103 Dobroyd] where my grandfather, Benjamin Kitson [& his Business Partner Charles Sharman] were short term owners/leases in 1900’s? And, how do I discover how many people would have been employed in a Mill of 70 looms and 2,000 spindles? This is for my family not-for-profit website being http://www.amos-denison.life NB: This is a real “modern”[2018] website and the address is 100% accurate – some web/blog pages need updating to accommodate such an address!

Thank you David Denison